High Precision Aluminum Alloy Plate Market, Global Outlook and Forecast 2023-2032

Global High Precision Aluminum Alloy Plate Market continues to demonstrate robust growth, with its valuation reaching USD 3.2 billion in 2024. According to the latest industry analysis, the market is projected to grow at a CAGR of 5.8%, reaching approximately USD 5.1 billion by 2032. This expansion is primarily driven by increasing demand from semiconductor manufacturing, aerospace applications, and the growing electric vehicle sector where precision and lightweight properties are paramount.

High Precision Aluminum Alloy Plates are engineered materials offering exceptional dimensional accuracy (±0.05mm tolerance), superior surface finish, and enhanced mechanical properties through specialized rolling and heat-treatment processes. These characteristics make them indispensable in high-tech manufacturing environments where precision is non-negotiable.

Download FREE Sample Report:

https://www.24chemicalresearch.com/download-sample/235587/high-precision-aluminum-alloy-plate-market

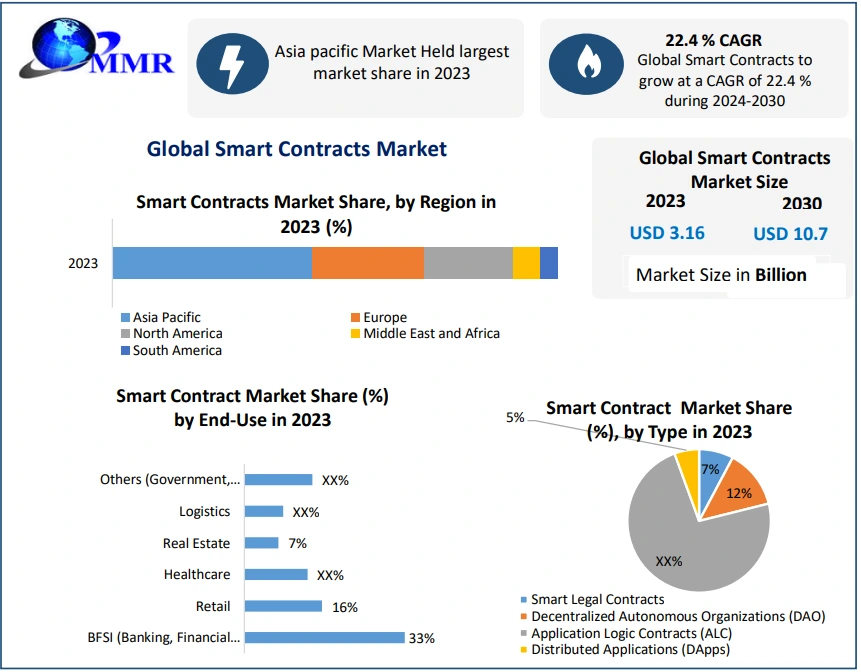

Market Overview & Regional Analysis

Asia-Pacific dominates global production, accounting for over 45% of market share, with China leading both consumption and manufacturing capacity. Japan and South Korea maintain technological leadership in ultra-high precision alloys, though Chinese producers are rapidly closing the gap through substantial R&D investments. The region's dominance stems from its concentrated electronics and semiconductor manufacturing ecosystem.

North America represents the second-largest market, with the U.S. accounting for 78% of regional demand, primarily driven by aerospace and defense applications. Europe shows balanced growth across automotive and industrial sectors, while emerging markets in Latin America and Africa present untapped potential for future expansion, albeit with current infrastructure limitations.

Key Market Drivers and Opportunities

The semiconductor equipment sector accounts for nearly 40% of total demand, as these plates are essential for wafer handling systems and deposition equipment. The global semiconductor market's projected 6-8% annual growth directly fuels this demand. Furthermore, aerospace applications are growing steadily, with aluminum alloys constituting about 60% of modern airframe materials.

Significant opportunities exist in electric vehicle components, particularly battery enclosures where precision aluminum alloys offer ideal combinations of lightweight and thermal properties. Emerging technologies like quantum computing present new frontiers, with specialized cryogenic-compatible alloys already in prototype testing at research facilities.

Challenges & Restraints

The market faces several hurdles including high production costs - establishing a precision rolling line requires over $50 million capital investment. Technical challenges in ultra-thin plate production (below 0.3mm) and supply chain vulnerabilities for rare alloying elements also constrain growth. Additionally, intellectual property protection has become increasingly difficult as competitors seek to replicate proprietary alloy formulations.

Market Segmentation by Type

High Precision

Ultra High Precision

Market Segmentation by Application

Semiconductor Manufacturing Equipment

LCD Manufacturing Equipment

Industrial Molds

Others

Market Segmentation by Alloy Series

1000 Series

2000 Series

5000 Series

6000 Series

7000 Series

Report Scope

This report presents a comprehensive analysis of the global and regional markets for High Precision Aluminum Alloy Plates, covering the period from 2024 to 2032. It includes detailed insights into the current market status and outlook across various regions and countries, with specific focus on:

Market size and growth projections

Detailed segmentation by type, application, and alloy series

Competitive landscape and market share analysis

In addition, the report provides in-depth profiles of key industry players including:

KOBE STEEL, Ltd.

UACJ Corporation

Nippon Light Metal

Constellium SE

Hydro Extrusion

Arconic Corporation

The analysis examines technological trends, raw material supply dynamics, and the impact of regulatory frameworks across different regions. Special attention is given to the evolving requirements of end-use industries and emerging application areas that are shaping future demand patterns.

High Precision Aluminum Alloy Plate Market, Global Outlook and Forecast 2023-2032

Global High Precision Aluminum Alloy Plate Market continues to demonstrate robust growth, with its valuation reaching USD 3.2 billion in 2024. According to the latest industry analysis, the market is projected to grow at a CAGR of 5.8%, reaching approximately USD 5.1 billion by 2032. This expansion is primarily driven by increasing demand from semiconductor manufacturing, aerospace applications, and the growing electric vehicle sector where precision and lightweight properties are paramount.

High Precision Aluminum Alloy Plates are engineered materials offering exceptional dimensional accuracy (±0.05mm tolerance), superior surface finish, and enhanced mechanical properties through specialized rolling and heat-treatment processes. These characteristics make them indispensable in high-tech manufacturing environments where precision is non-negotiable.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/235587/high-precision-aluminum-alloy-plate-market

Market Overview & Regional Analysis

Asia-Pacific dominates global production, accounting for over 45% of market share, with China leading both consumption and manufacturing capacity. Japan and South Korea maintain technological leadership in ultra-high precision alloys, though Chinese producers are rapidly closing the gap through substantial R&D investments. The region's dominance stems from its concentrated electronics and semiconductor manufacturing ecosystem.

North America represents the second-largest market, with the U.S. accounting for 78% of regional demand, primarily driven by aerospace and defense applications. Europe shows balanced growth across automotive and industrial sectors, while emerging markets in Latin America and Africa present untapped potential for future expansion, albeit with current infrastructure limitations.

Key Market Drivers and Opportunities

The semiconductor equipment sector accounts for nearly 40% of total demand, as these plates are essential for wafer handling systems and deposition equipment. The global semiconductor market's projected 6-8% annual growth directly fuels this demand. Furthermore, aerospace applications are growing steadily, with aluminum alloys constituting about 60% of modern airframe materials.

Significant opportunities exist in electric vehicle components, particularly battery enclosures where precision aluminum alloys offer ideal combinations of lightweight and thermal properties. Emerging technologies like quantum computing present new frontiers, with specialized cryogenic-compatible alloys already in prototype testing at research facilities.

Challenges & Restraints

The market faces several hurdles including high production costs - establishing a precision rolling line requires over $50 million capital investment. Technical challenges in ultra-thin plate production (below 0.3mm) and supply chain vulnerabilities for rare alloying elements also constrain growth. Additionally, intellectual property protection has become increasingly difficult as competitors seek to replicate proprietary alloy formulations.

Market Segmentation by Type

High Precision

Ultra High Precision

Market Segmentation by Application

Semiconductor Manufacturing Equipment

LCD Manufacturing Equipment

Industrial Molds

Others

Market Segmentation by Alloy Series

1000 Series

2000 Series

5000 Series

6000 Series

7000 Series

Report Scope

This report presents a comprehensive analysis of the global and regional markets for High Precision Aluminum Alloy Plates, covering the period from 2024 to 2032. It includes detailed insights into the current market status and outlook across various regions and countries, with specific focus on:

Market size and growth projections

Detailed segmentation by type, application, and alloy series

Competitive landscape and market share analysis

In addition, the report provides in-depth profiles of key industry players including:

KOBE STEEL, Ltd.

UACJ Corporation

Nippon Light Metal

Constellium SE

Hydro Extrusion

Arconic Corporation

The analysis examines technological trends, raw material supply dynamics, and the impact of regulatory frameworks across different regions. Special attention is given to the evolving requirements of end-use industries and emerging application areas that are shaping future demand patterns.