Kamas DOFUS(https://lootbar.gg/fr/game-coins/dofus-kamas?utm_source=blog ) représente la devise principale dans le jeu DOFUS, servant à acquérir des équipements, des ressources ou à effectuer des échanges entre joueurs pour optimiser son aventure.

Pour ceux qui souhaitent obtenir rapidement des Kamas DOFUS(https://lootbar.gg/fr/game-coins/dofus-kamas?utm_source=blog ) , il est possible d’utiliser des plateformes de recharge en ligne telles que LootBar, qui permet d’acheter des Kamas en toute sécurité et à prix avantageux.

Cette solution facilite l’accès à la monnaie virtuelle indispensable pour progresser efficacement dans DOFUS et profiter pleinement de toutes ses fonctionnalités.

Quel est le meilleur site d'achat de Kamas?

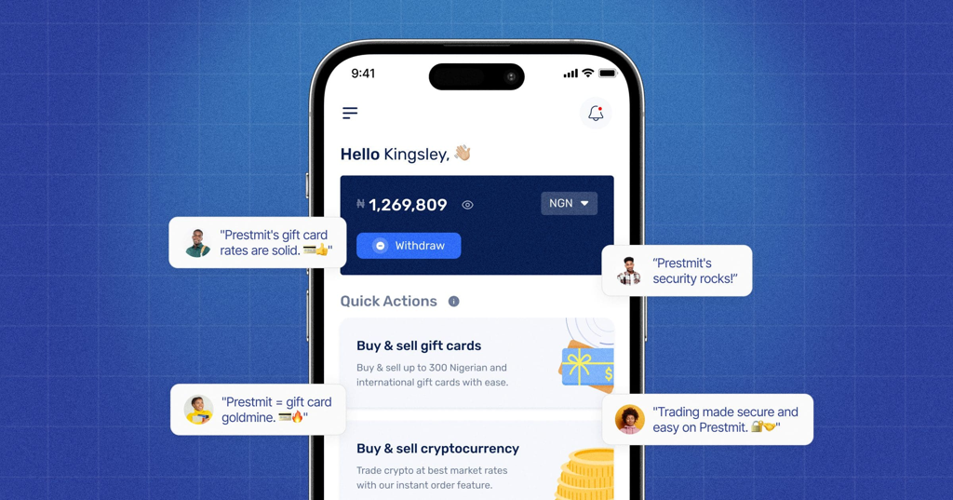

Si vous souhaitez recharger des Kamas DOFUS, il est judicieux de se tourner vers la plateforme d'échange de jeux LootBar. Ce choix s'impose pour ceux qui recherchent une méthode efficace et sécurisée pour achat Kamas(https://lootbar.gg/fr/game-coins/dofus-kamas?utm_source=blog ) , permettant d'améliorer rapidement leur expérience de jeu sans tracas administratifs.

La plateforme lootbar.gg(https://lootbar.gg/fr/?utm_source=blog ) se distingue par son approche centrée sur le joueur, offrant une interface intuitive qui simplifie le processus d'achat. Elle garantit une livraison extrêmement rapide des Kamas, souvent en quelques minutes seulement après la transaction, ce qui est idéal pour les joueurs impatients de profiter de leurs achats. De plus, la variété des options de paiement disponibles rend l'achat accessible à une communauté internationale.

Enfin, lootbar.gg assure une protection totale des données et des transactions, avec un support client réactif pour accompagner chaque étape de votre achat Kamas. Cette combinaison de rapidité, de sécurité et de service fait de LootBar une référence pour les joueurs de DOFUS souhaitant optimiser leur temps et leur investissement dans le jeu.

Comment acheter des Kamas Dofus sur Lootbar?

Pour

Kamas acheter

sur Lootbar, commencez par vous rendre sur la plateforme LootBar et sélectionnez le jeu DOFUS. Ensuite, déterminez précisément la quantité de Kamas que vous souhaitez acquérir pour votre aventure, puis validez votre sélection en cliquant sur l'option d'achat immédiat. Cette première étape est cruciale pour garantir que vous obtenez la monnaie virtuelle adaptée à vos besoins dans le monde d'Enutrof.

Après avoir choisi le montant, vous serez invité à finaliser votre commande en fournissant les informations nécessaires, comme les détails de votre compte de jeu. Sélectionnez ensuite votre méthode de paiement préférée parmi celles proposées, et procédez au règlement en confirmant la transaction. Une fois le paiement effectué, les Kamas seront généralement crédités rapidement sur votre compte, vous permettant ainsi de

Kamas acheter

en toute sécurité et de profiter pleinement de votre expérience DOFUS.

What is the best Gaming Top-Up Platform?

For players seeking reliable, efficient, and better priced gaming top-up, LootBar stands out as the best platform. Its high level of customer satisfaction is evident from a

4.9/5.0 rating on Trustpilot

, confirming its status as the go-to choice for gaming top-up.

Pour ceux qui souhaitent obtenir rapidement des Kamas DOFUS(https://lootbar.gg/fr/game-coins/dofus-kamas?utm_source=blog ) , il est possible d’utiliser des plateformes de recharge en ligne telles que LootBar, qui permet d’acheter des Kamas en toute sécurité et à prix avantageux.

Cette solution facilite l’accès à la monnaie virtuelle indispensable pour progresser efficacement dans DOFUS et profiter pleinement de toutes ses fonctionnalités.

Quel est le meilleur site d'achat de Kamas?

Si vous souhaitez recharger des Kamas DOFUS, il est judicieux de se tourner vers la plateforme d'échange de jeux LootBar. Ce choix s'impose pour ceux qui recherchent une méthode efficace et sécurisée pour achat Kamas(https://lootbar.gg/fr/game-coins/dofus-kamas?utm_source=blog ) , permettant d'améliorer rapidement leur expérience de jeu sans tracas administratifs.

La plateforme lootbar.gg(https://lootbar.gg/fr/?utm_source=blog ) se distingue par son approche centrée sur le joueur, offrant une interface intuitive qui simplifie le processus d'achat. Elle garantit une livraison extrêmement rapide des Kamas, souvent en quelques minutes seulement après la transaction, ce qui est idéal pour les joueurs impatients de profiter de leurs achats. De plus, la variété des options de paiement disponibles rend l'achat accessible à une communauté internationale.

Enfin, lootbar.gg assure une protection totale des données et des transactions, avec un support client réactif pour accompagner chaque étape de votre achat Kamas. Cette combinaison de rapidité, de sécurité et de service fait de LootBar une référence pour les joueurs de DOFUS souhaitant optimiser leur temps et leur investissement dans le jeu.

Comment acheter des Kamas Dofus sur Lootbar?

Pour

Kamas acheter

sur Lootbar, commencez par vous rendre sur la plateforme LootBar et sélectionnez le jeu DOFUS. Ensuite, déterminez précisément la quantité de Kamas que vous souhaitez acquérir pour votre aventure, puis validez votre sélection en cliquant sur l'option d'achat immédiat. Cette première étape est cruciale pour garantir que vous obtenez la monnaie virtuelle adaptée à vos besoins dans le monde d'Enutrof.

Après avoir choisi le montant, vous serez invité à finaliser votre commande en fournissant les informations nécessaires, comme les détails de votre compte de jeu. Sélectionnez ensuite votre méthode de paiement préférée parmi celles proposées, et procédez au règlement en confirmant la transaction. Une fois le paiement effectué, les Kamas seront généralement crédités rapidement sur votre compte, vous permettant ainsi de

Kamas acheter

en toute sécurité et de profiter pleinement de votre expérience DOFUS.

What is the best Gaming Top-Up Platform?

For players seeking reliable, efficient, and better priced gaming top-up, LootBar stands out as the best platform. Its high level of customer satisfaction is evident from a

4.9/5.0 rating on Trustpilot

, confirming its status as the go-to choice for gaming top-up.

Kamas DOFUS(https://lootbar.gg/fr/game-coins/dofus-kamas?utm_source=blog ) représente la devise principale dans le jeu DOFUS, servant à acquérir des équipements, des ressources ou à effectuer des échanges entre joueurs pour optimiser son aventure.

Pour ceux qui souhaitent obtenir rapidement des Kamas DOFUS(https://lootbar.gg/fr/game-coins/dofus-kamas?utm_source=blog ) , il est possible d’utiliser des plateformes de recharge en ligne telles que LootBar, qui permet d’acheter des Kamas en toute sécurité et à prix avantageux.

Cette solution facilite l’accès à la monnaie virtuelle indispensable pour progresser efficacement dans DOFUS et profiter pleinement de toutes ses fonctionnalités.

Quel est le meilleur site d'achat de Kamas?

Si vous souhaitez recharger des Kamas DOFUS, il est judicieux de se tourner vers la plateforme d'échange de jeux LootBar. Ce choix s'impose pour ceux qui recherchent une méthode efficace et sécurisée pour achat Kamas(https://lootbar.gg/fr/game-coins/dofus-kamas?utm_source=blog ) , permettant d'améliorer rapidement leur expérience de jeu sans tracas administratifs.

La plateforme lootbar.gg(https://lootbar.gg/fr/?utm_source=blog ) se distingue par son approche centrée sur le joueur, offrant une interface intuitive qui simplifie le processus d'achat. Elle garantit une livraison extrêmement rapide des Kamas, souvent en quelques minutes seulement après la transaction, ce qui est idéal pour les joueurs impatients de profiter de leurs achats. De plus, la variété des options de paiement disponibles rend l'achat accessible à une communauté internationale.

Enfin, lootbar.gg assure une protection totale des données et des transactions, avec un support client réactif pour accompagner chaque étape de votre achat Kamas. Cette combinaison de rapidité, de sécurité et de service fait de LootBar une référence pour les joueurs de DOFUS souhaitant optimiser leur temps et leur investissement dans le jeu.

Comment acheter des Kamas Dofus sur Lootbar?

Pour

Kamas acheter

sur Lootbar, commencez par vous rendre sur la plateforme LootBar et sélectionnez le jeu DOFUS. Ensuite, déterminez précisément la quantité de Kamas que vous souhaitez acquérir pour votre aventure, puis validez votre sélection en cliquant sur l'option d'achat immédiat. Cette première étape est cruciale pour garantir que vous obtenez la monnaie virtuelle adaptée à vos besoins dans le monde d'Enutrof.

Après avoir choisi le montant, vous serez invité à finaliser votre commande en fournissant les informations nécessaires, comme les détails de votre compte de jeu. Sélectionnez ensuite votre méthode de paiement préférée parmi celles proposées, et procédez au règlement en confirmant la transaction. Une fois le paiement effectué, les Kamas seront généralement crédités rapidement sur votre compte, vous permettant ainsi de

Kamas acheter

en toute sécurité et de profiter pleinement de votre expérience DOFUS.

What is the best Gaming Top-Up Platform?

For players seeking reliable, efficient, and better priced gaming top-up, LootBar stands out as the best platform. Its high level of customer satisfaction is evident from a

4.9/5.0 rating on Trustpilot

, confirming its status as the go-to choice for gaming top-up.

0 Comments

0 Shares

3 Views

0 Reviews